Company Profile

Weihai Hifei Marine Co., Ltd.

Established in Year 2004

Established in Year 2004

Employee: 320

Employee: 320

Factories: 3 locations, 60000sqm

Factories: 3 locations, 60000sqm

Main products: FRP RIB, ALU RIB, foldable tender, SUP board

Main products: FRP RIB, ALU RIB, foldable tender, SUP board

Production capacity: 300+ boat & sup/ day

Production capacity: 300+ boat & sup/ day

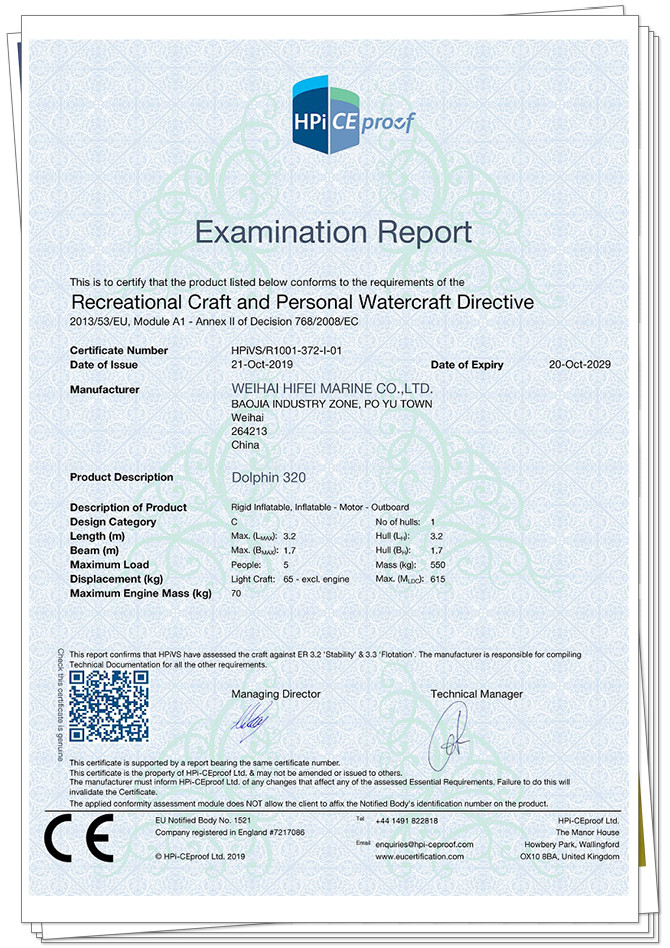

Certificate: CE, UKCA , ISO9001, ISO6185

Certificate: CE, UKCA , ISO9001, ISO6185

Till end of 2021, Hifei produced totally 455788pcs of boats and SUP boards for customers from 70+ countries

Till end of 2021, Hifei produced totally 455788pcs of boats and SUP boards for customers from 70+ countries

Applications of our product: rowing boat, diving boat, swimming platform, fishing boat, sightseeing boat, passenger boat, rescue boat, cruising boat, transport boat, patrol boat, military boat, etc.

Applications of our product: rowing boat, diving boat, swimming platform, fishing boat, sightseeing boat, passenger boat, rescue boat, cruising boat, transport boat, patrol boat, military boat, etc.

Our Mission

To create value for customers, to create a stage for employees to realize their dreams

Our Values

Loyal, enterprising and effectively managed employees are the company’s greatest asset

Available Sizes

1.6m ~ 6m foldable tender

1.85m ~ 7.5m RIB

Developing Target

3m ~ 10m luxurious RIB, Aluminum-hull RIB

Main Materials

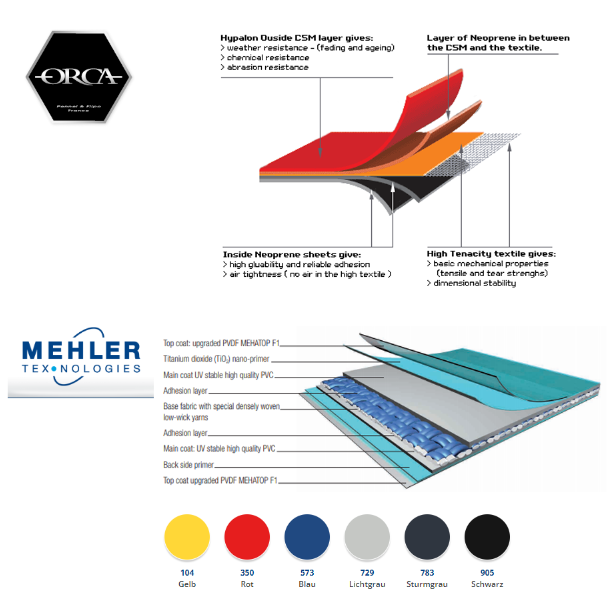

1.Hypalon fabrics from Pennel Flipo Orca, France:

With the base cloth of high tenacity polyester 1100 dtex or 1670 dtex, Hypalon fabrics are extremely resistant to tough conditions and particularly adapted to tropical climate. They present excellent resistance to UV, hydrolysis, and hydrocarbon. This fabrics are hand glued with a specific two part adhesive (neoprene glue mixed with RFE hardner).

2.The most commonly used PVC material for all our RIBs are from Mehler Texnologies, Germany. Mehler Valmex PVC is one of the best material for making inflatable boats, ideal for UV resistance in so-called temperate climate regions. Weldable, bondable, weather proof, abrasion resistant, crease resistance, UV resistant, stain resistant, and dimensionally stable.

3.Some of foldable tenders are made of PVC made in China, eg “Sijia” or “Huasheng”.

4.Glue from Henkel, Korea

Our Quality Control

1.We have an internal laboratory to test batch raw materials to avoid unqualified materials into production:

1)Strength test

2)High temperature air tightness joint strength test

3)Salt spray test

4)Accelerated aging test

2.All workshops are equipped with air conditioner and dehumidifier. The production environment is strictly controlled for temperature and humidity.

3.All products are equipped with a production process card to ensure the follow-up quality control in the later stage of the product.